Manufacturing Infra

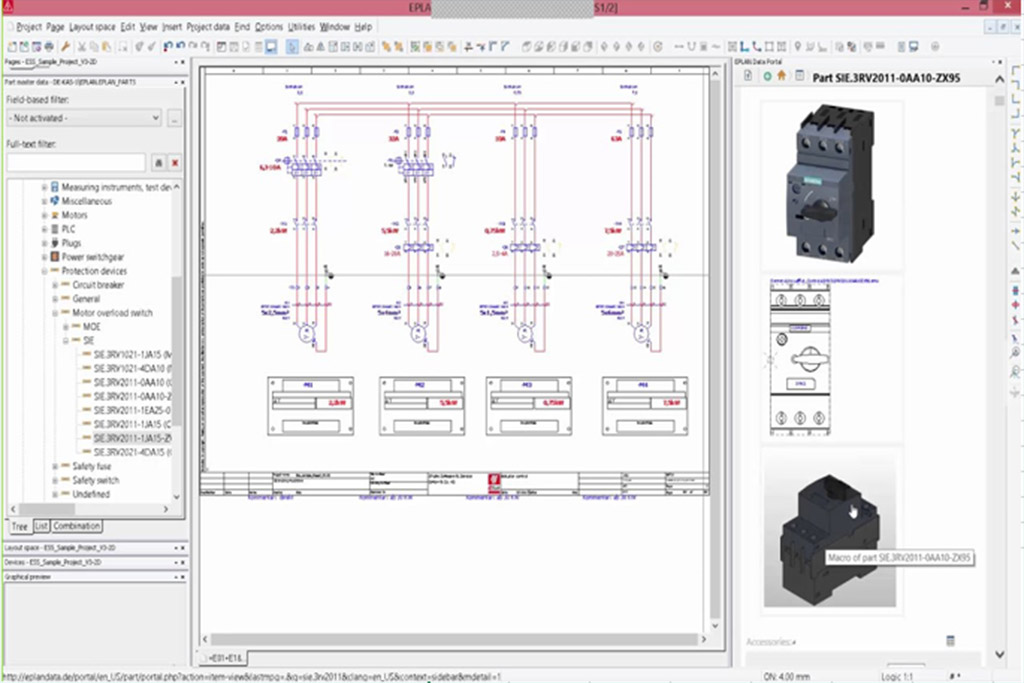

ELECTRICAL DESIGN

We have world – class software E-PLAN to create precise and detailed designs. It is more than electrical CAD the most powerful software for electrical design.

FEATURES OF E-PLAN

- All - in - one project: create the schematics, store the project data.

- Easily integrate component data from hundreds of manufacturers into the project.

- Use automated formatting for lists and forms.

- Derive important documentation from the schematics with just a few clicks: for production, sales and project approvals.

- Enter changes just once and apply those changes to the entire project.

- Latest version of a project is always available.

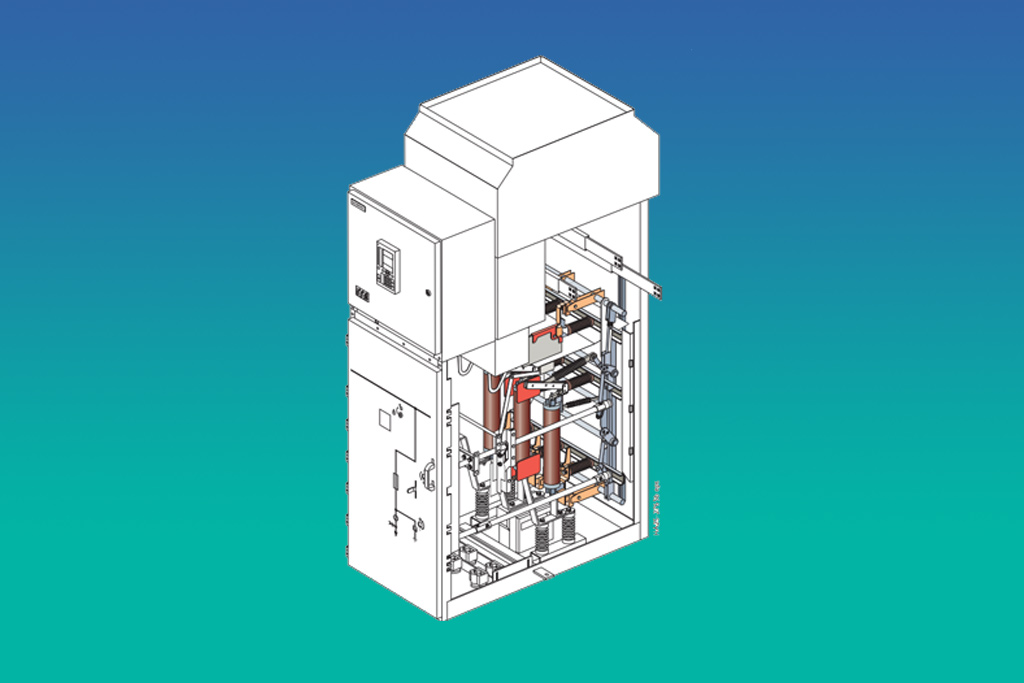

MECHANICAL DESIGN

We have world – class software SOLID WORKS to create precise and detailed designs IN 3D format for each and every panel that is being manufactured

The most powerful software for electrical design.

FEATURES OF SOLIDWORKS

- Part and Assembly Modelling and 2D Drawings.

- Specialized Design Tools for Weldments, Moulds, and Sheet Metal.

- Design and Manufacturability Checks.

- ECAD - MCAD Collaboration.

- Intelligent CAD Libraries.

- Manufacturing Cost Analysis.

- CAD Standards and Drawings Checking.

- Electrical Harness, Piping, Tubing, and Duct Design.

CNC TURRET & LASER MACHINES, POWDER COATING

EXPEL PROSYS’s advanced manufacturing facility is where precision meets innovation to redefine electrical panel production. Equipped with world-class machinery, including AMADA (JAPAN) punching machines, CNC bending machines from ACCUPRESS (CANADA) & YEWAI (CHINA), MEHTA (INDIA) Laser Cutting & NAMSUNG (KOREA) for bus bar fabrication, we ensure unmatched precision and efficiency.

Our cutting edge pre treatment and powder coating plant, featuring an 7 tank process with pre heater & inhouse test lab guarantees exceptional finishing, enhancing both durability and aesthetics. With a relentless focus on quality, technology, and innovation, we continue to set new benchmarks in electrical panel manufacturing.

QUALITY & TESTING

EXPEL PROSYS is committed to delivering uncompromising quality across its products, processes, and services. Every product undergoes a rigorous four- stage manufacturing process, with stringent in-process quality checks at each step. To ensure efficiency and consistency, the company employs industry-best Total Quality practices, including Lean & Flow manufacturing, adherence to well defined SOPs, and 5S storage systems to minimize downtime. Continuous improvement is ingrained in the culture, ensuring corrective actions are implemented to prevent recurrence.

List of Major Testing Equipments

- 3-Phase High End Numerical Relay Testing Kit.

- Primary Injection Kit.

- Insulation Tester.

- AC / DC High Voltage Tester.

- Breaker Timing Measurement Kit.

- Contact Resi. Measurement Kit.

- Conductivity Meter.

- Paint Thickness Meter.

- Lug Pull Tester.